Safety Solutions

Hyundai Material Handling Equipments are designed with safety first in the interior space Enhanced safety device ensures safe and comfortable work only You can concentrate.

DUO sensitive ELR (Emergency Locking Retractive) Seat belt

As both acceleration and angle sensors are built into the seatbelt, the belt will retract automatically if the vehicle overturns due to sudden braking or while operating at low speed, preventing the operator from being ejected from the vehicle.

*7 ton or lighter engine/sit down electric

Seat belt interlock

When set to MCU, the operation sequence error detection function disables start-up of the vehicle when the operator’s seat belt is not buckled.

*4.5 ton or lighter engine/sit down electric -powered: OPT

Hill Start Assist Control System

HAC : Hill Start Assist Control System

It is possible to smoothly and safely restart the vehicle preventing the push back on the hill through the Vehicle Hill Sensor, equipped in MCU, and Auto-Parking Brake.

*22,25,30,33D-9H

Mast tilting degree and status display

The mast is set up perpendicularly to the ground surface by connecting the mast grade sensor on the side of the mast with the MCU, thus improving work efficiency thus improving work efficiency and safety in operation.

*All 4.5 ton or lighter engine and electric models: OPT

Load weight indication

When lifting a load, a change in hydraulic pressure of the lift line is converted to a measurement of weight displayed in real time, and a warning is given at the time of overload.

*All 9 series models

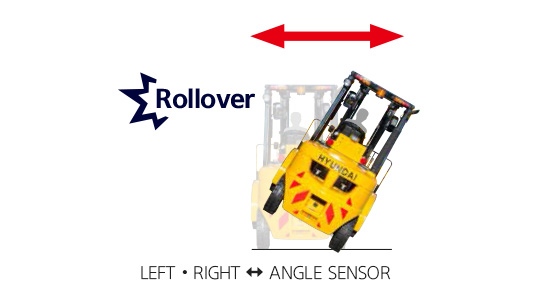

Machine inclination indication

The grade (left) and slope (right) sensors are built into the MCU and provide the grade and slope status information of the vehicle connected with the road surface condition in real time.

*All engine models.

Fork camera and LCD monitor

A camera installed on the side of fork provides the operator with the front view of the carriage via the LCD monitor.

*Electric reach/electric: OPT

Curve control

Curve control limits travel speed based on turning radius, reducing speed for a smooth, precise turning operation for the driver.

*All electric models

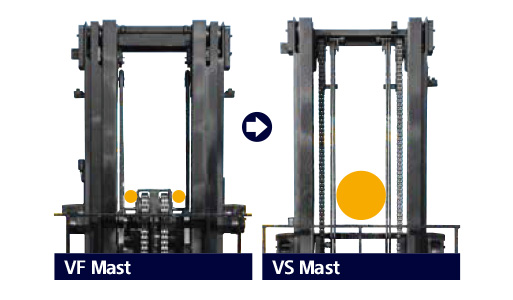

VS mast

A wider front view is available by placing the free lift cylinders located at the center of the 2-stage free lift mast on both the left- and right-hand sides, thus improving working efficiency and safety.

* 1~3.5 ton, 11~16 ton : OPT

TS mast

A wider front view is available by placing the free lift cylinders located at the center of the 3-stage free lift mast on both the left- and right-hand sides, thus improving working efficiency and safety.

* 1~30 ton : OPT

Mast Accumulator for load cushioning

The accumulator installed at the side of mast prevents the lift cylinder from moving up and down when driving on an uneven, rugged road surface in order to prevent the load from shaking.

*All 16 ton or lighter engine models: OPT

Auto Parking Brake

If the operator leaves the seat while the gear lever is in neutral, the parking brake is automatically engaged to secure safety, and is automatically released upon the operator’s return to the seat.

*All engine-type models.

Speed limit setting

As the vehicle’s speed limit can be set in consideration of the user’s environment, accidents resulting from violations of the speed limit can be prevented. Full-load work is possible even when operating the vehicle while following the speed limit.(The setting speed will appear in the same position as that of Mast tilting degree and status display)

*All engine and electric-powered models.

Directional Switch and Horn on Lift Lever

The directional (fwd/rev) switch and horn button are conveniently placed on the lift lever for ease of operation and quick horn warning response.

*Sit down electric: OPT

Rear Camera

When reversing the vehicle and simultaneously using the lift, it is possible to work safely watching the rear view through the rear camera linked with reverse gear.

*25-9H~30tons engine models

Front Camera

In order to solve the inconvenience of the fork position confirmation between the mast structures of the large forklift equipped with the three-stage mast, the front camera can be installed on the left and right sides of the carriage. Fork position can be confirmed through the driver’s seat monitor.

*5 ~ 30tons engine models

Fork Camera

During lifting the rack located at high position, it is hard to see the fork insert point with the naked eye. The CCTV camera enables safe work by checking the location of pallet through the monitor under headguard. Normally, the camera is installed on the side of fork or front of carriage.

*BRJ, BRP Models

Tilt Lock (Standard)

When engine stops during lifting, even though tilt lever is operated forward unintentionly, tilt lock prevents the load from falling onto floor or worker.

*All Models

Operator Presence Sensing System (OPSS)

When the operator is not in the seat during engine working or stop, in order to prevent driving/hydraulic levers from operating unexpectedly, operator presence sensing system has been applied. (When the system work, it is limited to operate the forward/backward, mast lifting/lowering and tilting.

*All Models excluding standing models

Blue Spot

When worker near forklift overlook warning alarm in case of reverse drive in warehouse, blue spot illuminate the rear of vehicle for worker to recognize the vehicle approach.

*3.5ton or lighter Engine Models, Electric Models

Low Leak Valve at Lift Down (Standard)

When the load should be maintained in high position for some time after lift of the heavy load, check valve have been installed to prevent the sudden drop owing to oil leak inside lift line.

*Engine Models (below 5ton, 11~16 ton), Electric Models

Prevention of Sudden Drop when Rupture of Piping (Standard)

If hydraulic piping is ruptured during lift, the mast drops suddenly and causes safety accident. To avoid such unexpected drop, the protector valve is installed to control flowrate under lift cylinder and ensure the safety of operator and worker near workplace.

*All Models

During Engine (Motor) Stop, Steering (HPS: Hydraulic Power Steering) (Standard)

When engine or motor stops during driving, to avoid locking the handle while hydraulic supply is cut off to steering device, the vehicle can move to repair shop by manual pumping function of steering pump.

*All Models

During Engine Stop, Mast Lowering Fuction (RCV) (Standard)

When engine stops during lifting, in preperation for situation that downstream of control valve is blocked. Pilot control system enables the load to unload safely on the floor using the hydraulic power saved in accumulator.

*Engine Models (5~25ton, Cabin Tilting Models)

Forward/Backward Switch & Horn on Lift Lever

Forward/Backward switch and horn are installed on side of lift lever. The improved lever pervents safety accident by rapid change of driving direction and quick operation of horn in emergency.

*5ton or lighter Engine Models (9series), Sit-down Electric Model